Wondering what’s the deal with septic lift stations? You’re in the right place! In this blog post, we’ll dig deep into all things lift station-related.

From what it is, why it’s important, to even when to wave it goodbye, we’ve got you covered. Buckle up, as we dive into the nitty-gritty of these unsung heroes of our homes!

Let’s Talk About Septic Lift Stations!

As we dive deeper into the world of septic systems, it’s time to meet a special player: the septic lift station.

These guys come into play when gravity can’t do the job on its own, usually thanks to tricky land slopes or specific situations.

Septic Lift Station: The Basics

So, what’s a septic lift station? Also known as a pump station, it’s a gadget-packed unit designed to move wastewater uphill.

In essence, it ‘lifts’ the waste from your septic tank and sends it off to the drain field for more treatment.

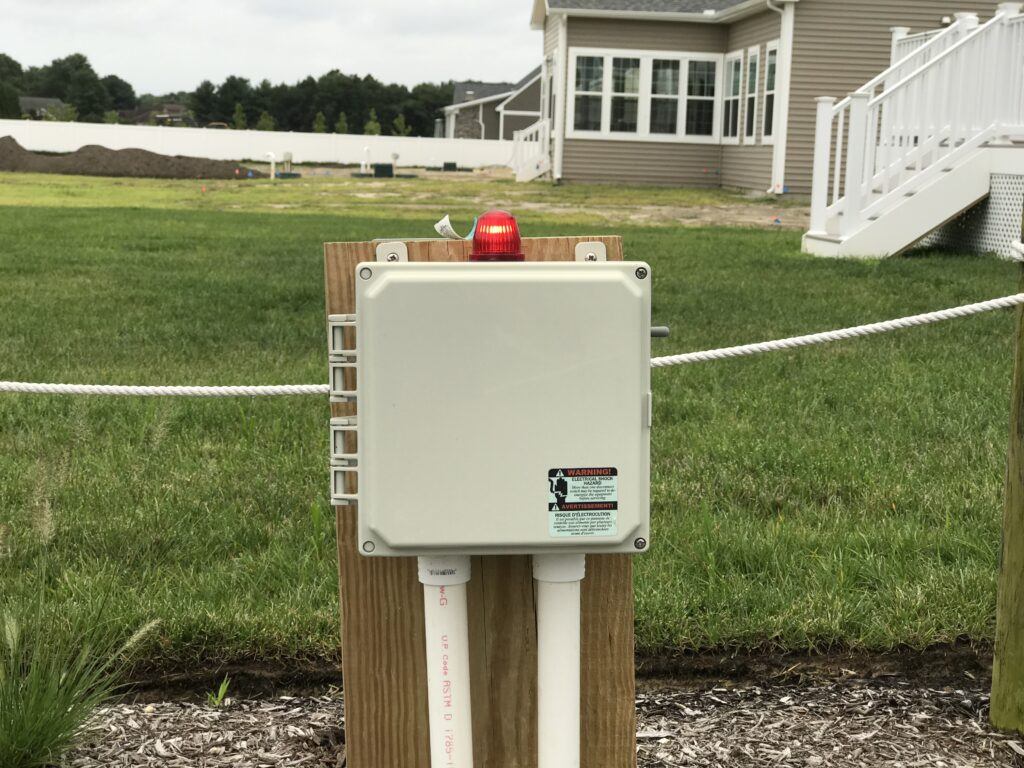

Imagine a well-like pit, called a wet well. Now, equip it with strong pumps, valves, and a control panel with an alarm system – that’s your septic lift station.

These pumps defy gravity, lifting wastewater upward.

The alarm?

It’s your system’s way of saying, “Hey, the water level’s too high! There might be a problem with the pumps or valves.”

Simplex Vs. Duplex: What’s the Difference?

Lift stations come in two main types: Simplex and Duplex.

Simplex Lift Stations

Simplex stations come with a single pump. They’re perfect for smaller spots, like a single home or a small building.

The good news? They’re cost-friendly and easy to use.

The downside? No backup pump, so if the main pump goes kaput, your system’s on hold till it gets fixed.

Duplex Lift Stations

Duplex stations, on the other hand, feature two pumps. These powerhouses are great for bigger projects, like commercial buildings or housing complexes.

The bonus? If one pump fails, the other steps in to keep things running smoothly.

Ready for more? Stick around as we next dive into the nitty-gritty of septic lift station components.

What Makes Up a Septic Lift Station?

A septic lift station isn’t just a simple pit with a pump.

Oh no, it’s a team of components, all playing their part to move wastewater when gravity alone can’t cut it.

So, let’s pop the hood and get to know these hardworking parts!

The Wet Well: The Starting Point

First up, we’ve got the wet well, or sump. This basin holds the incoming wastewater.

Its size matters because it needs to store enough wastewater to avoid frequent pump activations, which could wear out the pump too soon.

Pumps: The Heavy Lifters

The pumps are the heart of a lift station. They hustle to move the wastewater from the wet well to the septic tank or drain field.

The number and size of the pumps can vary, depending on the type of lift station and the amount of wastewater it handles.

Floats or Sensors: The Regulators

Meet the float switches or sensors. They hang out in the wet well, controlling the pumps. When the wastewater level gets high enough, these switches tell the pump to get moving.

Once the level drops down, they tell the pump to take a break.

The Alarm System: The Watchdog

The alarm system is like your lift station’s watchdog. If the water level in the wet well gets too high (which might mean a pump problem), this system will sound the alarm.

It’s a crucial piece in preventing overflows and serious issues.

Control Panel: The Brain

Next, we have the control panel. This is where the operation of the pumps, floats, and alarm system is managed.

It can also have features for manual pump operation and silencing that loud alarm.

Check Valves, Discharge Pipe, and Power Supply: The Support Team

Check valves stop any backflow of wastewater into the wet well when the pumps are off. The discharge pipe carries the wastewater from the pump to the septic tank or drain field.

And let’s not forget the power supply – it keeps all the components working. It’s a good idea to have a backup power supply or generator for those unexpected power outages.

Every single piece of a septic lift station plays a specific role.

Together, they make sure the wastewater from your home is efficiently transported to the septic tank or drain field, no matter how your property’s laid out.

In our next section, we’ll take a look at how a lift station works, which will give you an even better understanding of these components.

A Day in the Life of a Septic Lift Station

Now that we’re friends with the parts of a septic lift station, let’s see how they all come together for the daily grind of managing your wastewater.

From Home to Wet Well

Everyday wastewater from your house – think showers, dishwashing, toilet flushes – makes a pit stop in the wet well of the lift station.

Keeping an Eye on the Level

As the wet well fills up, our trusty float switches or sensors keep tabs on the water level.

Each float switch has a job: one springs into action when the well is full enough to pump out (‘turn-on’ level), and another gives the pump the ‘all-clear’ to stop when the well’s empty enough (‘turn-off’ level).

Pump it Up!

Once the wastewater reaches the ‘turn-on’ level, the float switch gets the pump going.

The pump then flexes its muscles, pushing the wastewater up the discharge pipe and onto the septic tank or drain field for more treatment.

That uphill journey is what earns the lift station its name.

Time for a Break

After the pump’s done its job and the wastewater level hits the ‘turn-off’ level, the float switch tells the pump to chill.

This on-and-off dance keeps the wet well from overflowing and the pump from running dry, saving your equipment from damage.

Alarm Bells Ringing

But what if the water level keeps rising even after hitting the ‘turn-on’ level? Maybe the pump’s on a break, or there’s a power outage.

That’s when the alarm float switch steps in, setting off the alarm system.

This gives homeowners or maintenance personnel the heads up to fix things before the wet well overflows or other big problems pop up.

Keeping the right balance of waste in the lift station is key. Too much on-and-off action can wear out the pump too soon.

But if the pump doesn’t get to work enough, the waste could hang out in the well too long. That could stink, literally, or even back up your system.

Getting to know this process can help you keep an eye on your septic system and spot any issues early.

Up next, we’ll chat about how to install a septic lift station and what to consider to make sure it’s a success.

Show Your Septic Lift Station Some TLC

Keeping your septic lift station in top shape doesn’t have to be daunting. A little regular TLC can go a long way.

Homeowner Homework

You can do a few simple tasks to help keep your lift station running smoothly:

Eyes and Ears On: Be alert to any unusual sights or sounds. An alarm sounding? Strange noises from the pump? Or maybe a smell that’s not quite right? These could hint at issues.

Keep It Clean: Keep the area around your lift station tidy. This helps avoid accidental damage and keeps the way clear for maintenance or repair work.

Take Notes: If you can, keep a record of pump cycles or run times. If these start to change, your lift station might be trying to tell you something.

Time to Call in the Pros

Your septic lift station is a bit of a diva – it needs some professional pampering. Here’s what the experts should handle:

Pump Inspection: An annual check-up can spot signs of wear and tear on the pump. This way, the pros can suggest fixes or replacements before it’s too late.

Electric Check: The electrical parts of your lift station, including the alarm system, need a regular once-over to ensure they’re on the ball.

Deep Clean: Over time, solids can build up in the wet well, gumming up the works. Professionals can give it a good scrub, checking for damage along the way.

Ignoring your septic lift station’s maintenance could spell trouble. Think pump failures, system backups, or overflows.

That could cost you a pretty penny in repairs, not to mention potential harm to the environment.

With regular care, your septic lift station can give you years of efficient service, saving you money and giving Mother Nature a break.

Next, we’ll talk about when it’s time to wave goodbye to your old septic lift station and welcome a new one. So stick around for more pearls of septic system wisdom!

Common Issues with Septic Lift Stations

Even with all that TLC, sometimes things can go wrong with your septic lift station. Here’s the lowdown on some common problems:

Trouble in Septic Paradise

Pump Failure: When your pump throws in the towel, it’s a big deal. Your waste won’t budge an inch. Alarms sounding, waste backing up, or overflow? Could be a kaput pump.

Lights Out: Power outages can bring your lift station to a standstill. If you’re prone to blackouts, a backup generator could be a lifesaver.

Float Switch Fuss: If your float switches go haywire, your pump might get confused. That can cause overflows or a dry-run pump, damaging your kit.

Clogs and Blockages: Debris can build up in your wet well or discharge pipe. If your pump’s running non-stop or the water level’s not dropping, you might have a blockage.

Alarm Failure: If your alarm system conks out, you might miss critical warnings. Regular tests can help keep your alarm alert.

Don’t DIY!

Some problems, like a tripped circuit breaker or a finicky alarm, might be easy to fix. But remember, your septic lift station is a complex beast.

Getting it wrong could be harmful and even dangerous.

If your pump’s acting up, you’re dealing with float switch problems, blockages, or your alarm system’s given up the ghost, it’s time to call the pros.

They can diagnose and fix the issue safely and effectively, saving you from further headaches and protecting the environment too.

In our next section, we’re talking about when it’s time to bid farewell to your old septic lift station and roll out the red carpet for a new one.

Knowing When to Say Goodbye to Your Septic Lift Station

Like everything else, your septic lift station won’t last forever. But a well-cared-for one could stick around for 20 years or more.

Lifespans can swing based on installation quality, maintenance, waste type, and how much action it sees.

Is It Time for a New One?

Non-stop Drama: If you’re always dealing with breakdowns despite regular tune-ups, your lift station might be on its last legs.

Old Equipment: If your lift station is creeping up in years, you might want to start thinking about a replacement.

Sky-high Maintenance Bills: If upkeep costs are on the rise, it might be cheaper in the long run to swap it out for a newer model.

New Demands: If there’s a change in the amount or type of waste – like after a home extension or getting a new hot tub – you might need an upgrade.

Making Your Septic Lift Station Last

Regular Tune-ups: Annual inspections and timely fixes can add years to your lift station’s life.

Smart Flushing: Watch what you flush. Wipes, hygiene products, fats, oils, and grease can block the works and overwork your pump.

Backup Power: Power cuts can do a number on your lift station. A backup generator can keep things running and give your pump a longer life.

8 Pump Owners Need to Know

This video from RC Worst and Co. goes over 8 tips and tricks for your septic pumping system.

In essence, to keep your pump system in top shape, it’s important to use a test gauge at startup and understand the importance of an upper ball bearing in identifying quality pumps.

Make sure to choose pumps with easy warranty processes and remember you can’t get professional-grade ones from big box stores – you’ll find them at a distributor.

Lastly, knowing your system well, controlling what you flush, and learning how to manually start your pump can save you from a lot of hassle down the line.

Conclusion

And that’s a wrap, folks! We hope you’ve enjoyed this journey down into the world of septic lift stations. Remember, these systems are key to keeping our homes fresh and waste-free.

Regular maintenance, smart usage, and timely replacements can make all the difference. Thanks for sticking with us, and here’s to keeping your home running smoothly!

Greetings, I hav a situation where our septic lift station will need to pump an uphill rise of about 12′ with a run of around 75′, then down a fairly steep hill dropping about 40′ with a run of 100′ before it gets to the drain field. Any special challenges we might face?

Thank you for stopping by. I am not an expert on this topic, but based on my research these are some factors you may need to consider (please consult a professional):

First things first, the pump. It has to be strong enough to push the waste uphill for 12 feet. This is called ‘head height’. But it’s not just about the hill – the pump also needs to deal with resistance in the pipe. This depends on things like the pipe’s size, length, and even how bendy it is.

By the way, the downhill part might seem easier? Well, it’s a longer route, so more resistance there. Again, you need to choose your pipe wisely. Bigger pipes cause less resistance, but they also cost more.

Now, let’s talk about check valves. They prevent waste from flowing back when the pump is off. Also, don’t forget about venting. It’s key for the pump to work well and for gases to escape.

Also, look out for any breaks or leaks, especially when going downhill. A tiny leak can lead to a lot of waste lost and that’s bad for the environment.

Remember, your pump relies on electricity. What happens if there’s a power cut? Consider a backup plan like a generator or a spare pump.

Finally, terrain makes maintenance tricky. Make sure the pump and pipes are easy to get to for regular check-ups.

Now, this is a lot to take in. My advice? Consult a local pro. They’ll know the local laws and conditions and help you find the right equipment.

It would appear that there could be a possible siphon issue based on the length uphill and the length downhill you may not get it to stop sucking water even with the pump off.

Hi- we have a septic lift station that does not appear to have a vent pipe. Does it need one?? I’m told the cistern/wet well could collapse if we don’t vent it.

I have a lift station basin that is situated above ground on a cement foundation. Looking for ways to insulate it during winter weather events. Any ideas? Thanks. GS

In cold climates, when wastewater is lifted to the drain field and the pump shuts off, the check valves keep the water from flowing downslope back into the tank. the line would have water in it. What keeps this water from freezing in the line?